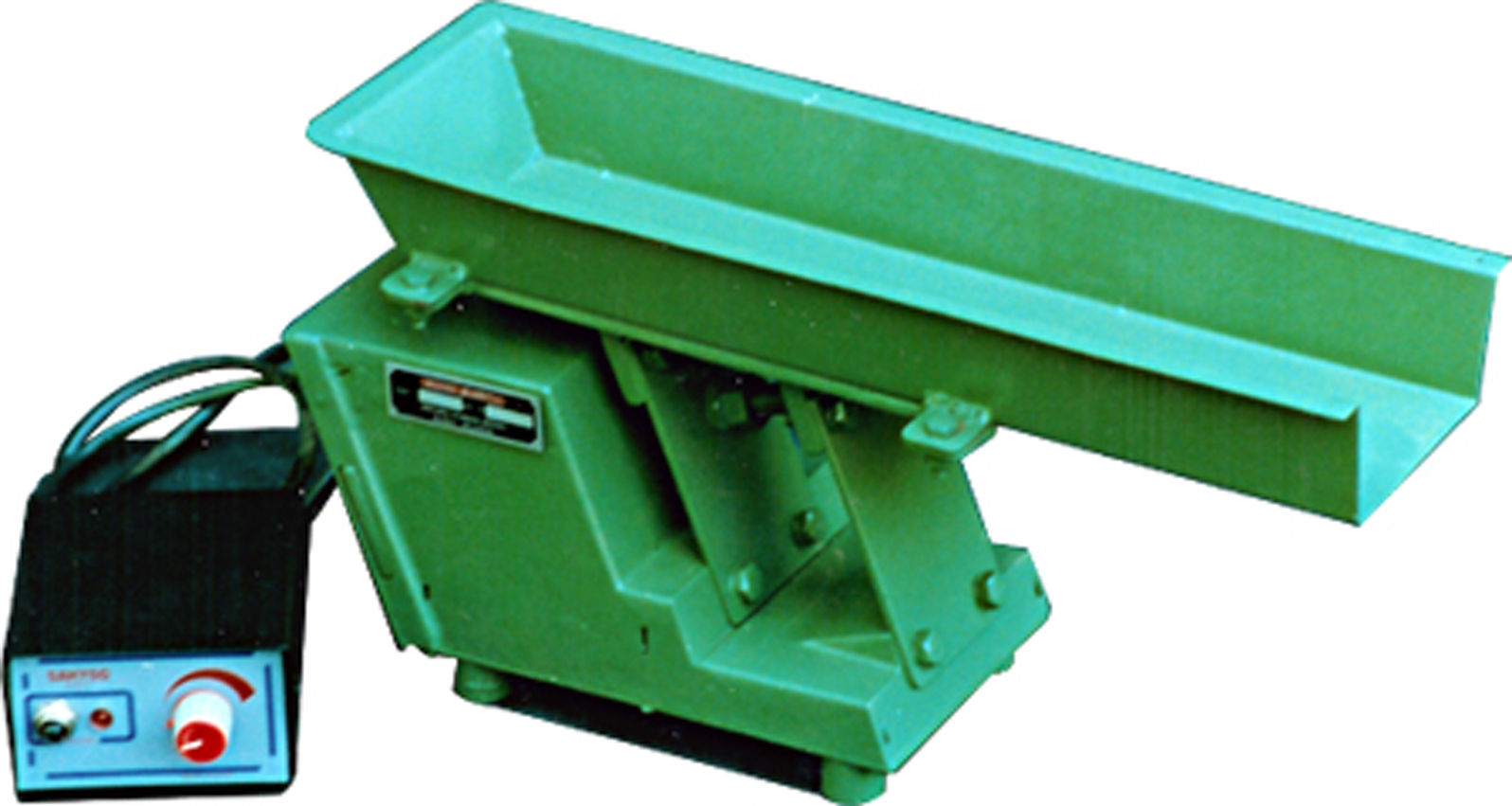

Volumetric Vibratory Feeders

Product Details:

- Usage Industrial

- Condition New

- Product Type Volumetric Vibratory Feeders

- Color Sliver

- Power Source Electric

- Voltage 220 Volt (v)

- Warranty 1 Years

- Click to View more

X

Volumetric Vibratory Feeders Price And Quantity

- 1 Piece

Volumetric Vibratory Feeders Product Specifications

- Sliver

- New

- 220 Volt (v)

- 1 Years

- Industrial

- Electric

- Volumetric Vibratory Feeders

Volumetric Vibratory Feeders Trade Information

- Mumbai

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- 1 Piece Per Week

- 2 Week

- Wooden Packing

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Our clients can avail from us Volumetric vibratory feeders. These Volumetric Vibratory Feeders machines feed dry bulk materials We offer these Volumetric Vibratory Feeders machines with electronic controllers to regulate the feed rate by varying the vibrating intensity of an electromagnetic feeder. It also regulates the material depth by adjusting the opening between the hopper and the feeder. The volumetric feeder can be easily integrated with the load cell and precise weighed output can be obtained. This application is widely used in the packaging industry for packing of boxes, containers and pouches from few pms to few kgs as the case may be.Volumetric Vibratory Feeders Features:

- Simple design

- Flexible controls

- Dependable

- Long service life

- Four basic components:

- Supply hopper

- Hopper vibrator

- Vibrating feeder

- Support frame

- Electronic controllers to regulate the feed rate by varying the vibrating intensity

- Regulates the material depth by adjusting the opening between the hopper and the feeder

- Easy integration with the load cell

- Precise weighed output can be obtained

Volumetric Vibratory Feeders Applications:

- Packaging industry for packing of boxes, containers and pouches from few pms to few kgs

- Chemical and pharma Industries for dosing of powder and material

- Food Industry for dosing of colour and ingradients

- Crushing and pulverising machine doser.

Efficient Material Handling for Industrial Processes

Volumetric Vibratory Feeders are vital for industries requiring accurate and consistent bulk material feeding. Their precise control minimizes wastage and maximizes productivity. With an electric power source and strong construction, these feeders cater to industrial demands seamlessly. The adjustable feed rate and durable design make them suitable for diverse applications, from manufacturing lines to packaging facilities.

Reliable Quality and Support from India

Manufactured by a leading supplier and exporter in India, these feeders adhere to high quality standards. The silver-finish units are delivered new and covered by a one-year warranty against manufacturing defects. With a focus on reliability and efficient after-sales support, Indian manufacturers ensure that every feeder meets the performance expectations of global industrial clients.

FAQs of Volumetric Vibratory Feeders:

Q: How does a Volumetric Vibratory Feeder operate in an industrial setting?

A: The feeder uses controlled vibrations to move bulk materials uniformly and steadily onto conveyor belts or into processing machines, powered by an electric supply at 220 Volt (v).Q: What are the primary benefits of using a Volumetric Vibratory Feeder in manufacturing?

A: These feeders enhance efficiency by delivering precise material quantities, reducing wastage, and streamlining production processes for improved throughput and reliability.Q: Where can Volumetric Vibratory Feeders be installed?

A: They can be integrated into various industrial facilities, such as packaging plants, assembly lines, and processing units, making them versatile for multiple applications.Q: When should an industrial business consider investing in this feeder?

A: Businesses experiencing inconsistent feed rates, excess material wastage, or requiring automation in bulk material handling should consider upgrading to a vibratory feeder for better control and operational efficiency.Q: What warranty and support are provided with the purchase?

A: Each Volumetric Vibratory Feeder comes with a 1-year warranty, covering manufacturing defects. Reliable support is available from the Indian exporter, manufacturer, and supplier.Q: How does the silver color and new condition contribute to the products quality?

A: The silver finish enhances resilience against environmental factors, while the new condition guarantees optimal performance and durability right from installation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email