Vibratory Feeder Bowls

Product Details:

- Usage Industrial

- Condition New

- Size Standard

- Product Type Vibratory Feeder Bowls

- Power Source Electric

- Color Sliver

- Click to View more

X

Vibratory Feeder Bowls Price And Quantity

- 1 Piece

Vibratory Feeder Bowls Product Specifications

- Industrial

- New

- Standard

- Vibratory Feeder Bowls

- Electric

- Sliver

Vibratory Feeder Bowls Trade Information

- Mumbai

- Cash in Advance (CID), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C)

- 1 Piece Per Day

- 2-4 Week

- No

- Wooden Packing

- Asia, Australia, Central America, North America, Western Europe, Middle East, Africa, South America, Eastern Europe

- All India

Product Description

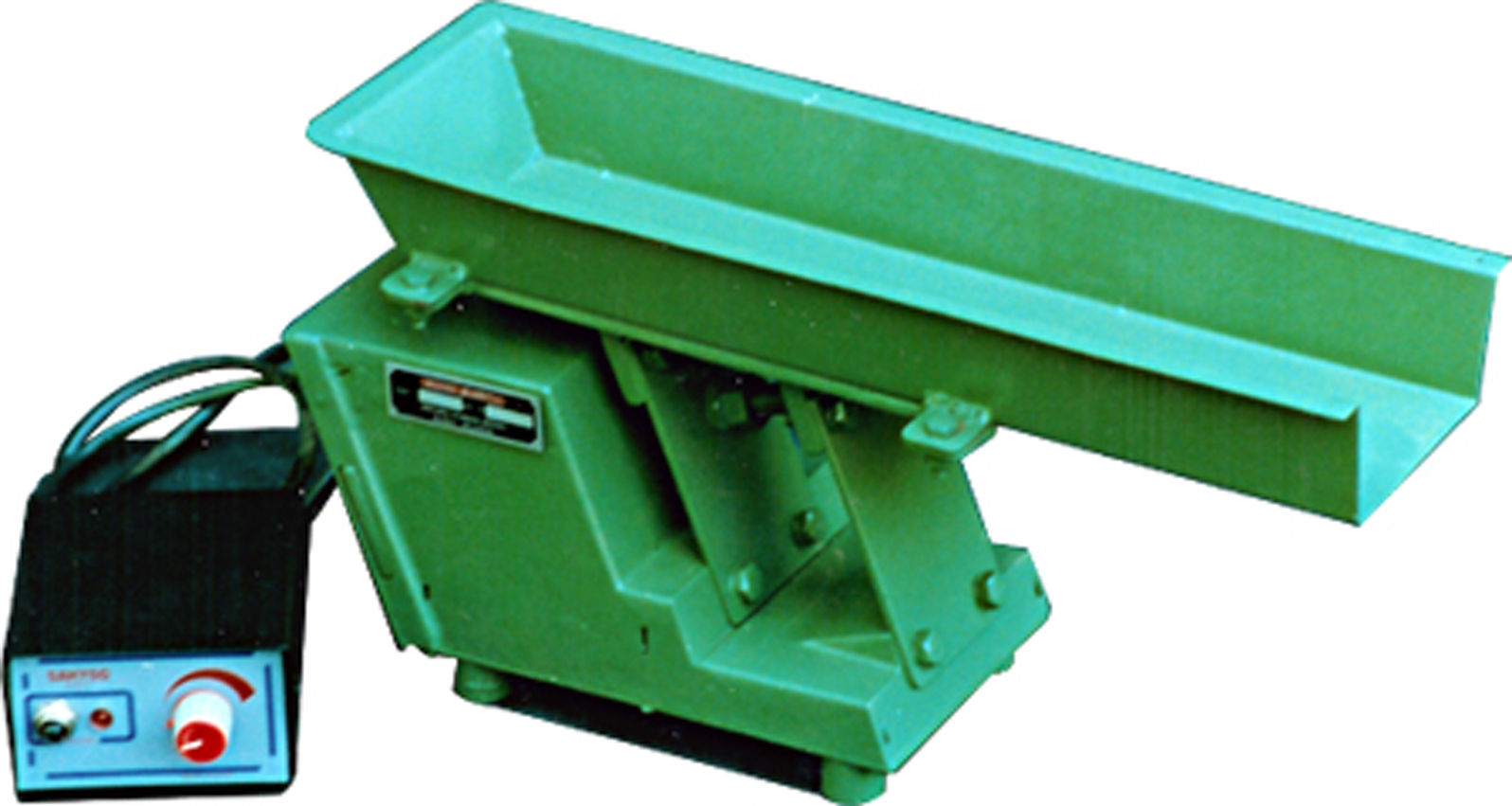

Vibratory Volumetric Feeder

We offer Vibratory Volumetric Feeder is an perfect tool of obtaining required output of components at specified feed rate. Mostly the main element of assembly engineering are Hopper, Stand and Vibratory feeder drive unit with tray and controller. These feeders are available in various forms such as custom made, and standard. Our standard feeders are designed and provided as per specific requirements and can be availed in six different models.

Applications:-

- Automobile Industries

- Fasteners

- Pharmaceutical

- Electronics

- Packaging

- Plastics

- Assembly line

Consistent Component Feeding

Our vibratory feeder bowls deliver dependable and accurate component feeding for diverse industrial applications. Utilized in manufacturing lines, they streamline the process of organizing and orienting parts, resulting in improved assembly speeds and minimized downtime. Their standard-sized configuration ensures compatibility with a wide array of automation systems.

Quality and Efficiency Assured

Manufactured using durable materials with a silver finish, these feeder bowls exemplify durability and resistance to industrial wear. Powered electrically, they consistently perform under demanding conditions, reducing maintenance requirements and enhancing operational efficiency for manufacturers.

FAQs of Vibratory Feeder Bowls:

Q: How are vibratory feeder bowls used in industrial settings?

A: Vibratory feeder bowls are essential for sorting, orienting, and feeding parts into automated production lines. They help streamline processes, reducing manual intervention and increasing throughput.Q: What benefits do standard-sized vibratory feeder bowls offer?

A: Standard-sized vibratory feeder bowls provide compatibility with various industrial machines, making them easy to integrate into existing assembly lines. They offer uniform feeding and reliable part handling for optimal productivity.Q: When should I consider using a new vibratory feeder bowl for my operations?

A: A new vibratory feeder bowl should be considered when upgrading equipment, expanding production, or replacing outdated systems to improve component feeding accuracy and minimize downtime.Q: Where can vibratory feeder bowls be utilized within a manufacturing facility?

A: These feeder bowls are commonly used at the start of assembly lines, in packaging areas, and wherever automated part feeding and alignment are necessary for efficient production.Q: What is the process of installing a vibratory feeder bowl supplied from India?

A: Once received, the vibratory feeder bowl can be installed by mounting it securely to the designated workstation, connecting the electric power source, and calibrating the feed settings according to the specific components being handled.Q: How do vibratory feeder bowls improve operational efficiency?

A: By automating the sorting and feeding of components, vibratory feeder bowls reduce labor costs, enhance process speed, and minimize the risk of human error during assembly, leading to greater overall operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email